PRIOR ART PRIOR ART

Even though torrefied wood was originally developed decades ago very little has ever been used for energy production. Most prior art processing methods used to make torrefied wood used “Convection” heat treatment. Biomass was exposed to hot gasses in a low oxygen chamber. Hot combustion gasses and or steam at up to 600 psi are used for heat transfer. Power plants complaints include non-uniform product and high cost. Less than 1% of biomass is used for energy production.

NEW PROCESS

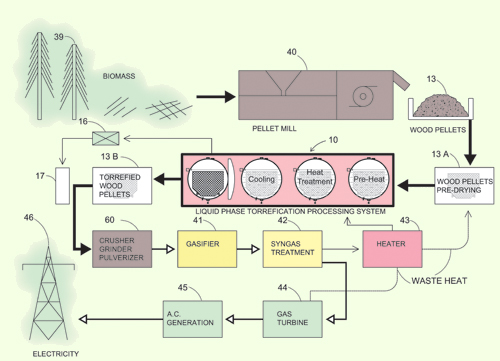

The CNFbiofuel™ system uses a new patented Liquid Immersion Torrefication Processing Technology. This uses “Conduction” heat treatment of wood pellets in multiple stages of heat transfer fluid. This process puts over 1000 times as many molecules in direct contact with the wood surface as compared to the prior art “Convection” heat treatment in a gas or steam process.

Preliminary testing of CNFbiofuel™ has shown positive results in increased heat content, friability and hydrophobic properties making it an ideal fuel. The produced fuel is ideal for solid fuel, atomization or a uniform feedstock for gasification.

CNFbiofuel™ has multiple patents pending on “Conduction” heat treatment. These include continuous flow and batch processing. Wood pellets are exposed to a series of “conduction” heat treatments temperatures that include Pre-Heat, Heat Treatment and Cooling. The advantage of this technology is that it puts 1,000 times as many heat transfer molecules in direct contact with the wood surface over convection methods. This results in faster and more efficient processing.

Biomass is first treated in the Pre-Heated with immersion heat transfer fluid at 300ºF. This drives out the moisture in the biomass. This moisture in the form of steam exits the system and is exhausted outside.

The biomass is then Heat Treated in immersed heat transfer fluid at 480ºF. This is where the VOC’s and any remaining moisture are driven out of the biomass. All the emissions are routed through a condenser where certain reclaimable liquids are captured. During this phase, the biomass is heated in an oxygen free environment and becomes torrefied. The biomass composition continues to take in heat without a change in temperature. This is the endothermic reaction phase where torrefaction occurs. The cellular structure and chemical composition changes during torrefaction. The biomass is then Heat Treated in immersed heat transfer fluid at 480ºF. This is where the VOC’s and any remaining moisture are driven out of the biomass. All the emissions are routed through a condenser where certain reclaimable liquids are captured. During this phase, the biomass is heated in an oxygen free environment and becomes torrefied. The biomass composition continues to take in heat without a change in temperature. This is the endothermic reaction phase where torrefaction occurs. The cellular structure and chemical composition changes during torrefaction.

The hot torrefied biomass is then Cooled in a heat transfer fluid at close to 300ºF. This cools the torrefied biomass to a safe temperature where combustion cannot occur. (Note: Wood can combust or oxidize when exposed to high heat treatment temperatures in air or in the presence of oxygen.) The torrefied biomass then exits the Cooling section where the torrefied biomass is air cooled and further draining of the heat transfer fluid occurs. The drained heat transfer fluid is captured and re-used in the process.

The heat transfer fluid is a paraffinic base material that has a very low vapor pressure at 480ºF. The vapor pressure at this condition is less than a two inch water column. Other plant based heat transfer fluids at higher vapor pressures can also be used in the process. The entire processing operation occurs at relatively low pressures and that reduces construction costs. The heat content of the heat transfer fluid is over 18,000 Btu per pound. The torrefied biomass does contain a small amount of heat transfer fluid and this enhances the heat content by the amount of heat transfer fluid on and within the treated biomass.

|